Why did so many vintage pen repairmen consider ink pH an issue at all over the past few decades?

Why does Greg Clark bother to measure pH in inks as listed in his "Ink Sampler"? Why does it matter?

The issue has been one of the founding beacons to Noodler's Ink, as every ink we make has a neutral pH** — absolutely neutral without exception. If a revolutionary ink is made that requires a non-neutral pH to function, as is expected once the elusive "white dye" is perfected, the label will clearly indicate a non-neutral pH and explain why.

**All Noodler's inks are pH neutral (pH Range 6.2 – 7.9). Average pH = 7.0

Contrary to much of the misinformation promulgated by a couple of self-proclaimed "experts," the main danger to pens is certainly not higher dye content in inks. After all, what do you pay for when buying an ink? It is NOT the water content! The dye content and dye characteristics, their intensity and durability, as well as their ability to rinse off plastic and ebonite/hard rubber (to test Noodlers: apply to sheet plastic or sheet rubber, allow to dry — even bake in the sun if it pleases — and spray with plain tap water. Youll witness it rinse off for yourself. So long as you rinse out your pens regularly, they will remain clean — it's just common sense) are the primary means of determining an ink's economic value.

If one is a large corporation, one would naturally reduce dye content to the extent that, in many cases, well known inks from the 1950's contain up to 11 times as much dye content as those very same brands do as they are produced today. Alas, perhaps they intend to sell bottled water instead of ink — it certainly boosts profits. Noodler's is not very profitable, but our conventional inks have the highest dye content on the market per given volume. If you have issues with higher dye content (as to why, is beyond my comprehension), you always have the option of adding tap water to the ink!

If it is not the dye that harms a pen, what does? Extremes in pH levels do. Think about it: Most piston fillers have brass, bronze, aluminum, and 8 alloy steel spirals, if not full mechanisms. Vintage Conklin Nozacs and Parker Vacumatics, as well as all metal telescoping piston fill mechanisms, are made of similar materials. The housing of aerometric fillers such as the Parker 51 often house aluminum alloys. Wahl Eversharp Gold Seal pens often have aluminum barrel housings. Most modern pens with metal trim use base metals beneath their gold plate consisting of either brass, bronze, aluminum, or 8 alloy steel. When a seal, sac or diaphragm fails, ink seeps beyond it and can reach the mechanism. It is at this point that pH becomes a big issue not only to people seeking archival inks – but those who have repaired vintage pens all their lives. The thousands of corroded vacumatic and Nozac, 51 and Eversharp, button and piston fill mechanisms I have seen over my lifetime were mostly do to the old fashioned, "indelible", "Permanent", "Registered", and "document" inks, all of which have pH levels that range between 1.5 and 4. Most well known, permanent, "water resistant," conventional inks are blue, black, and blue-black, found in Europe and Asia. They do not resist strong UV light, nor do they resist all the tools of the forger (certain carpet cleaners, bleaching techniques, etc…) — but they do resist water once dried. Noodler's opted to reject this much older technology for one reason — they ALL have highly corrosive pH levels.

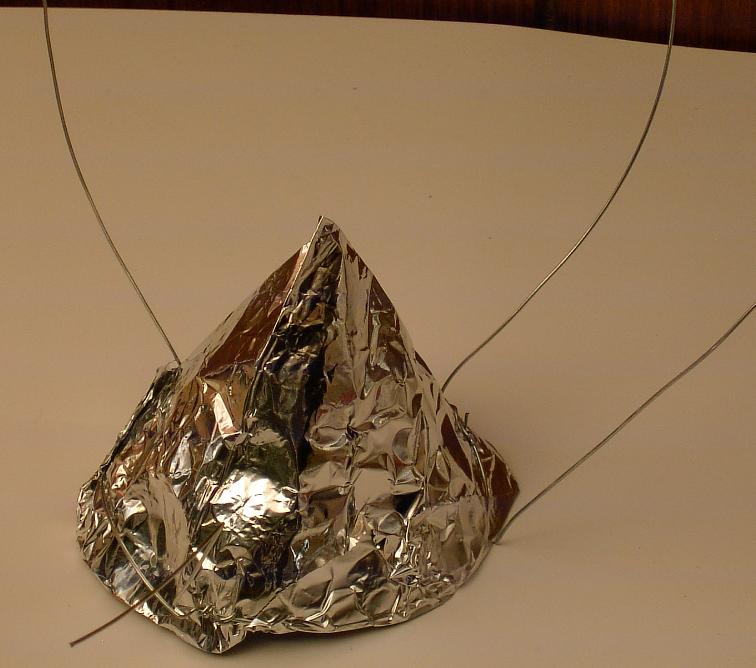

As usual, there will be doubters. I have designed a very simple experiment (see photos at the bottom of the page) to show anyone who cares to try it first hand what happens to metals when exposed to these inks (acids and the ambering of plastics as well as acids effects upon latex based sacs is an issue for another day). It only takes a few minutes to set up. First, form a 3 pronged wire loop stand…then form a funnel shape out of aluminum foil – or brass foil….or bronze foil…or copper foil…or tin foil….or zinc foil…or 8 alloy steel foil….you get the picture (I hope). Form the foil funnel to the stand…then pour in about one oz. of ink…and permit it to stand overnight.

A central European made "blue-black" ink of a make that is highly litigious was used in the unmarked cup as well as one from Western Europe and another from Asia. All have their pH levels marked…note that most of these inks have pH levels near 2 (if they were made neutral, they would precipitate — it is a very old ink technology that is highly dependent upon a strong acid level to function). Other inks have the opposite issue — pH levels of 9 to 11… these inks have the same results when they come into contact with metal.

Why use the metal foil experiments to show the danger of non-neutral pH levels? Simply because antique documents that have been filigreed with rot marks from the acid in such inks are nowhere near as dramatic or as effective in communicating the more immediate issues of non-neutral pH levels. There may be more work in making neutral pH inks – especially those that win the bulletproof designations – and the cost per volume may be much higher…but it is the only way to move our hobby forward in a meaningful way. It is a big reason why I began the company.

There are many reasons vintage repair people and Greg Clark have long considered pH an issue in ink – it is my hope that this simple demonstration that anyone can replicate with ease – can show this issue clearly to all concerned. I am certainly not advocating the use of aluminum in direct contact with ink – as even tap water will eventually corrode it…but there is a vast difference between corrosion that can take place overnight and corrosion that takes place simply due to the humidity in the air and its action over decades (upon which we do not have as much control vs. the simple choice of inks we buy…). Noodler's is not the only pH neutral ink on the market – but I do think one should take pH into account when making any ink purchase decision. You can trust that Noodler's is always pH neutral… & now you know the reasons why… I'm a pen collector and have repaired vintage pens since grade school – the mechanisms matter more to me in addition to any archival benefits within any ink formulation. The goal is to do the best one can – including consistently neutral pH** levels.